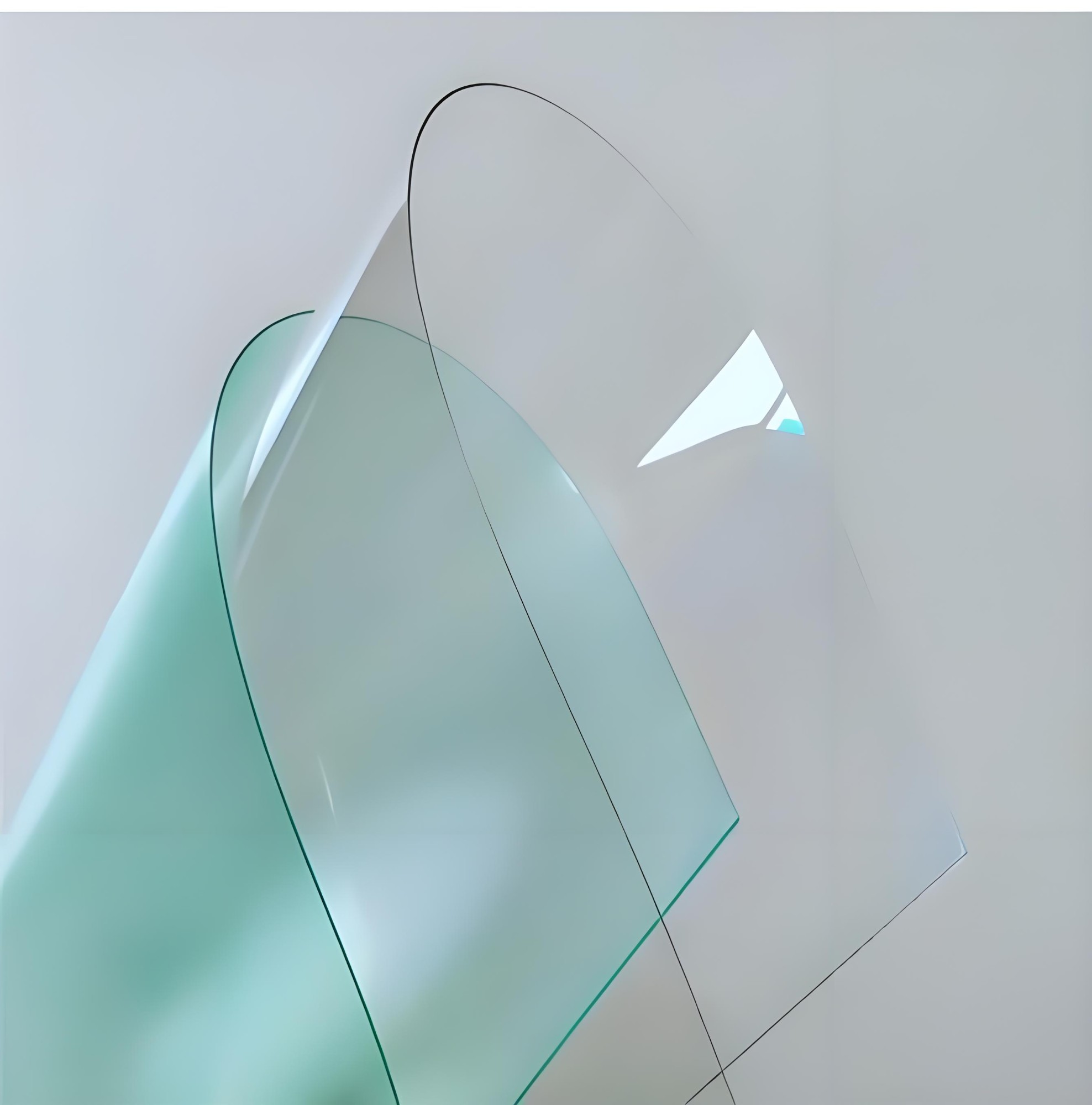

Printing Grade Polycarbonate Film The Versatile and Durable Solution for Your Industry

- Product Item : TOPPC10

- Category: Polycarbonate sheet

- Polycarbonate

- printing grade PC film

- PC board

- Printing Polycarbonate

- Product description:Printing Grade Polycarbonate Film The Versatile and Durable Solution for Your Industry, Printing Grade Polycarbonate Film factory from China,reliable manufacturer of Polycarbonate film ,Hi trust (fosh

The specifications of printing grade polycarbonate film:

| Property | Specification |

|---|---|

| Thickness | 0.005" - 0.1" (0.127 mm - 2.5 mm) |

| Transparency | ≥ 80% light transmission |

| Haze | ≤ 1.0% |

| Size | 915mm*1820mm |

| Impact Strength | > 30 ft-lb/in (Izod Notched) |

| Tensile Strength | 9,500 psi (65.5 MPa) |

| Elongation at Break | 100% - 150% |

| Flexural Strength | 13,500 psi (93.1 MPa) |

| Thermal Resistance | -40°C to 130°C (-40°F to 266°F) |

| Coefficient of Thermal Expansion | 6.8 x 10^-5 /°C |

| Dielectric Strength | 17.7 kV/mm (450 V/mil) |

| Surface Hardness | > 2H (pencil hardness) |

| Chemical Resistance | Resistant to many acids, alcohols, and oils |

| Moisture Absorption | 0.15% (24 hours, 23°C) |

| UV Resistance | UV stabilized (for outdoor applications) |

Printing grade polycarbonate film is a high-performance thermoplastic material renowned for

its excellent balance of clarity, strength, and versatility. Here’s a detailed description of its

properties, applications, and advantages:

Key Features:

-

Optical Clarity:

- High transparency, typically with over 90% light transmission.

- Low haze and high gloss finish, providing clear and vibrant printed graphics.

-

Durability:

- Exceptional impact resistance, much higher than glass and acrylic.

- High tensile and flexural strength, ensuring longevity and resilience.

- Resistant to cracking, breaking, and abrasion.

-

Thermal Resistance:

- Wide operating temperature range from -40°C to 130°C (-40°F to 266°F).

- Good dimensional stability under varying temperature conditions.

-

Chemical Resistance:

- Resistant to a wide range of chemicals, oils, and solvents.

- Suitable for environments where exposure to harsh substances is common.

-

Electrical Properties:

- Excellent electrical insulation properties.

- Suitable for applications requiring dielectric strength.

-

Surface Quality:

- Smooth, uniform surface ideal for high-quality printing.

- Available in various finishes, including matte, gloss, and textured.

Applications:

-

Graphics and Printing:

- Overlays, labels, nameplates, and control panels.

- Suitable for screen printing, digital printing, and thermal transfer printing.

-

-

Electronics:

- Membrane switches, touch screens, and display panels.

-

-

Automotive:

- Instrument panels, interior components, and dashboard overlays.

-

Industrial Applications:

- Control panels, machine covers, and protective barriers.

-

-

Signage:

- Backlit displays and illuminated signs.

-

Printing Techniques:

-

Screen Printing:

- Durable, vibrant colors suitable for high-volume production.

- Ideal for both large and small prints.

-

Digital Printing:

- High-resolution prints with intricate details.

- Flexible for short runs and custom designs.

-

Thermal Transfer Printing:

- Provides durable and resistant prints.

- Commonly used for barcodes, labels, and identification tags.

Advantages:

-

Ink Adhesion:

- Polycarbonate film requires surface treatment (e.g., corona treatment) to enhance ink adhesion.

- Proper preparation ensures durable and high-quality prints.

-

Environmental Resistance:

- UV stabilized grades available for outdoor applications.

- Maintains performance in harsh environmental conditions.

-

Versatility:

- Can be used in a wide range of applications across different industries.

- Available in various thicknesses and finishes to meet specific needs.

Considerations:

- Surface Treatment: Ensuring proper surface treatment is crucial for optimal ink adhesion and print quality.

- Compatibility: It is important to match inks and printing methods with the specific grade of polycarbonate film to avoid issues such as smudging or poor adhesion.

- Environmental Factors: Consideration of exposure to UV light, chemicals, and other environmental factors is important for ensuring the longevity of printed graphics.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Peter

Mobile:+86 18824809669

Tel:+86 18824809669

Whatsapp:8613923234163

Email:tonon888@gmail.com

Add:No 2 Shangliao Industrial zoon,Beijiao Shunde Foshan GD China

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands English

English Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu