Chemical Resistant Printing Polycarbonate PC Board for Long-Lasting and Durable Prints

- Product Item : TOPPC10

- Category: Polycarbonate sheet

- Polycarbonate

- plastic

- PC board

- Printing Polycarbonate

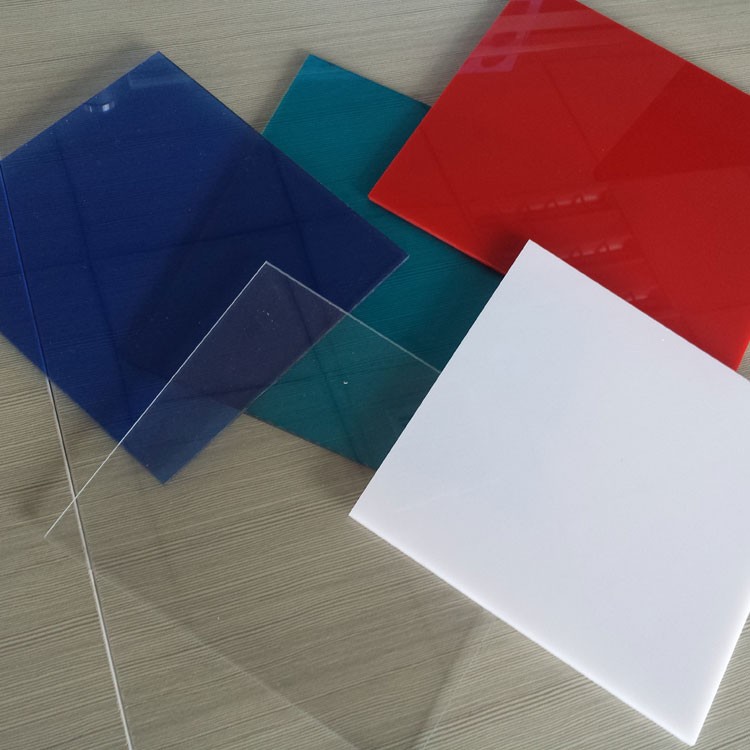

- Product description:Chemical Resistant Printing Polycarbonate PC Board for Long-Lasting and Durable Prints, Smooth and Versatile Printing Polycarbonate PC Board for Various Printing Techniques,Customizable Printing Polyc

Printing-grade polycarbonate (PC) boards are specialized materials designed to support high-quality printing while maintaining the intrinsic benefits of polycarbonate, such as durability, optical clarity, and heat resistance. These boards are widely used across various industries due to their excellent printability and robust physical properties. Here’s an in-depth description:

Material Properties

- High Impact Resistance: Polycarbonate is known for its ability to withstand significant impacts without cracking or breaking, making it ideal for demanding applications.

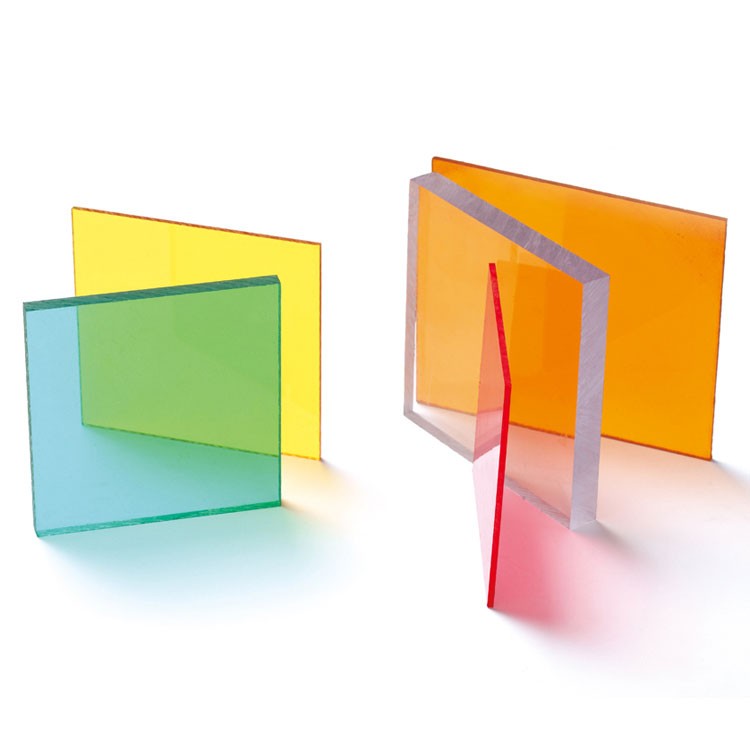

- Optical Clarity: The material offers excellent transparency, allowing for clear and vibrant prints. This is particularly beneficial for applications requiring visibility through the material, such as displays and signage.

- Heat Resistance: Polycarbonate can endure high temperatures, which is crucial during certain printing processes that involve heat.

- Flexibility and Dimensional Stability: The material can be easily thermoformed and retains its shape well under stress, ensuring consistent print quality.

Common Thicknesses

Printing-grade polycarbonate boards come in various thicknesses, typically ranging from 0.5 mm to 12 mm. The chosen thickness depends on the specific application requirements, such as the need for flexibility or structural strength.

Printing Methods

-

Screen Printing:

- Process: Ink is pushed through a stencil or mesh screen onto the polycarbonate surface.

- Advantages: Produces vibrant, durable prints and is cost-effective for large runs.

- Applications: Ideal for producing signage, control panels, and decals.

-

Digital Printing:

- Process: Uses digital inkjet technology to apply ink directly onto the polycarbonate.

- Advantages: High-resolution, detailed prints; suitable for custom and short-run productions.

- Applications: Perfect for custom graphics, prototypes, and small batch productions.

-

UV Printing:

- Process: Inks are cured using UV light immediately after being applied to the surface.

- Advantages: Fast drying, highly durable prints with excellent adhesion.

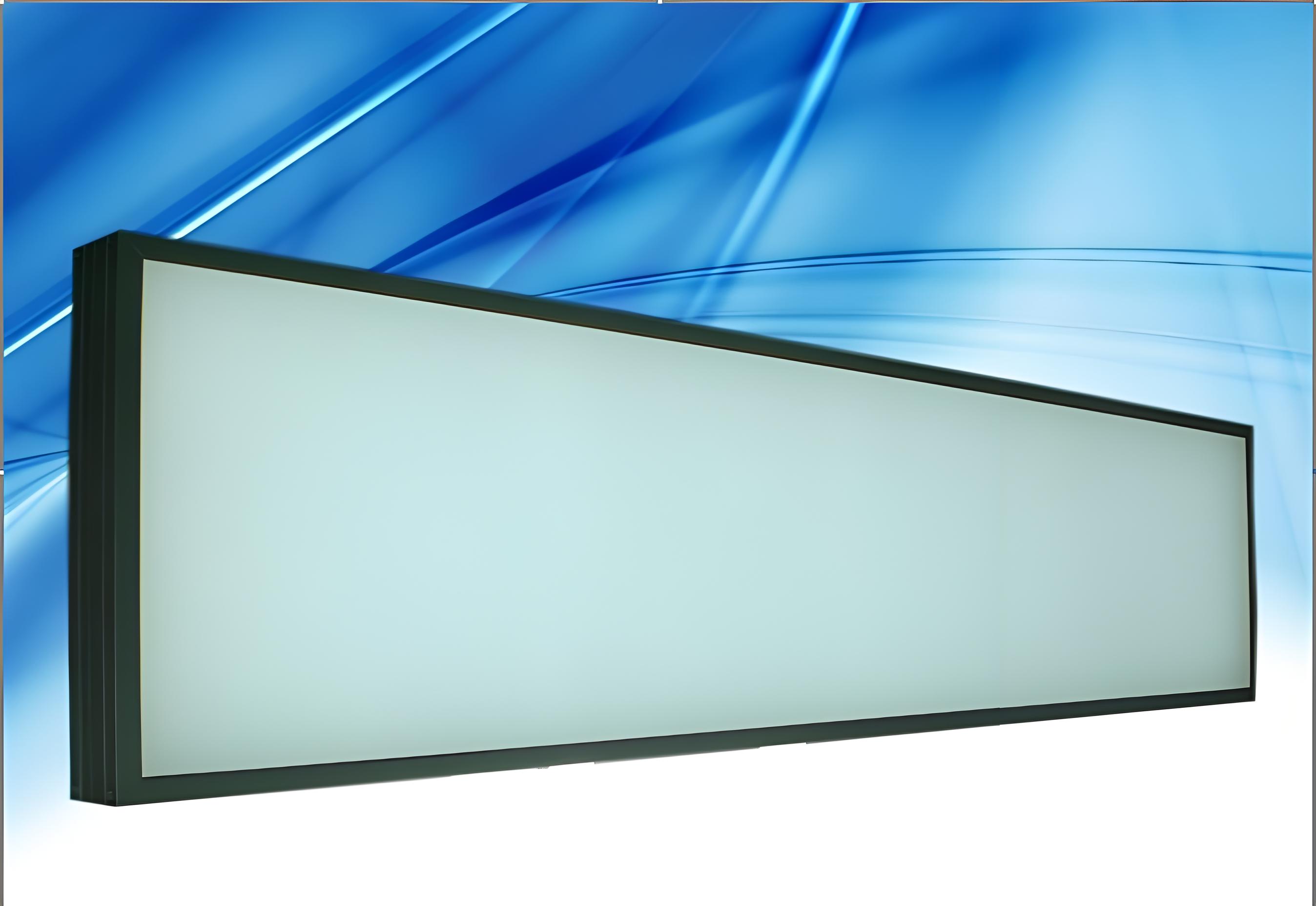

- Applications: Used for outdoor signage, industrial labels, and backlit displays.

-

Pad Printing:

- Process: Transfers ink from a silicone pad onto the polycarbonate.

- Advantages: Can print on irregular or curved surfaces.

- Applications: Suitable for electronic components, promotional items, and medical devices.

-

Laser Printing:

- Process: Uses a laser to etch or mark the polycarbonate surface.

- Advantages: Produces permanent, high-precision markings without the need for ink.

- Applications: Common for barcodes, serial numbers, and intricate designs.

Pre-Treatment and Finishing

- Surface Preparation: Cleaning the polycarbonate to remove any contaminants that might affect ink adhesion.

- Primers and Adhesion Promoters: Applying these substances can improve the adhesion and durability of the printed ink.

- Top Coating: Applying protective coatings to safeguard the printed surface from abrasion, UV damage, and chemical exposure.

Considerations

- Ink Compatibility: Selecting inks that adhere well to polycarbonate and meet the necessary durability and environmental resistance requirements.

- Environmental Conditions: Considering factors such as UV exposure, temperature fluctuations, and potential chemical exposure in the final application environment.

- Thickness of Polycarbonate: Ensuring the chosen printing method is compatible with the specific thickness and flexibility of the polycarbonate sheet.

- Color Matching: Ensuring accurate and consistent color reproduction, especially for applications requiring brand-specific colors.

Applications

- Signage: Both indoor and outdoor signs benefit from the durability and clarity of printed polycarbonate, making them long-lasting and visually appealing.

-

- Electronics: Control panels, display covers, and keyboards utilize printed polycarbonate for its durability, clarity, and resistance to wear and tear.

-

- Automotive: Instrument panels and various interior components are printed on polycarbonate to withstand the harsh conditions within vehicles.

-

- Industrial: Equipment labels, safety signs, and control panels are printed on polycarbonate due to its ability to endure harsh environments and provide clear, durable markings.

-

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Peter

Mobile:+86 18824809669

Tel:+86 18824809669

Whatsapp:8613923234163

Email:tonon888@gmail.com

Add:No 2 Shangliao Industrial zoon,Beijiao Shunde Foshan GD China